Koszyk (0)

Koszyk jest pusty

Do bezpłatnej dostawy brakuje -,--

Darmowa dostawa!

Podsumowanie zamówienia

Suma 0 zł

Cena uwzględnia rabaty

DARMOWA DOSTAWA OD 300 zł

Zapisz się do newslettera na dole strony i odbierz 5% rabatu na pierwsze zakupy.

-

-

Koszyk (0)Koszyk jest pusty

Do bezpłatnej dostawy brakuje -,--

Darmowa dostawa!Podsumowanie zamówienia

Suma 0 zł

Cena uwzględnia rabaty

-

-

Historia jedwabnictwa

Milanówek - stolica polskiego jedwabiu

Milanówek stolicą polskiego jedwabiu okrzyknięty został niemal 100 lat temu. Stało się to za sprawą Henryka i Stanisławy Witaczków, którzy założyli w 1924 r. Centralną Doświadczalną Stację Jedwabniczą. Od tego czasu do lat dziewięćdziesiątych XX wieku w Milanówku produkowane były różnego rodzaju tkaniny jedwabne. Firma założona przez Witaczków przetrwała różne zakręty historii, aby ostatecznie, po sprywatyzowaniu, zaniechać produkcji tkanin. Tak zakończył się rozdział związany z tkaniem jedwabiu w Milanówku, jednak tradycja malowania na jedwabiu przetrwała i przechodzi swój renesans.

Luma Milanówek kultywując milanowską tradycję dostarcza Państwu produkty - apaszki, szale i chusty - ręcznie malowane przez doświadczone artystki. Prace wykonywane są różnymi technikami, na różnych rodzajach tkanin jedwabnych - od satyny, przez krepę, po habotai. Malowanie każdej apaszki czy chusty jest bardzo czasochłonne. Niezwykła staranność podczas tworzenia przepięknych wzorów na jedwabiu sprawia, że każdy egzemplarz to małe arcydzieło. Powstająca dzięki niezwykłemu kunsztowi, ekskluzywna galanteria jedwabna, stanowi sztandarowy produkt naszej firmy.

Jak powstaje jedwab?

Gąsienice jednego z tysięcy gatunków motyli - jedwabnika morwowego - odżywiają się liśćmi morwy, dlatego też pierwszym etapem pozyskania jedwabiu jest hodowla drzew. Gąsienice, po kilku dniach przyjmowania solidnych porcji liści morwowych, zabierają się do budowania kokonu, w którym przepoczwarzą się w motyla. W tym czasie powstaje drogocenna nić o długości ok. 1,5 km. Zebrane kokony poddaje się działaniu gorącej pary, pod wpływem której ciasno utkaną cieniutką nić łatwiej jest rozwinąć. Potem następuje proces przędzenia, w wyniku którego otrzymywana jest jedwabna przędza, która jest surowcem do produkcji tkanin.

Skąd się wziął jedwab?

„Lśniący kolorami tęczy, zwiewny jak mgiełka, zmysłowy jak esencja pożądania”. Jedwab. Najbardziej luksusowe włókno naturalne, stosowane do produkcji wspaniałych tkanin, m.in. takich jak: satyna, twill, krepa, żorżeta, żakard.

Jedwab nie wychodzi z mody już od kilku tysięcy lat. Jego historia sięga aż czwartego wieku p.n.e. i starożytnych Chin. Chińczycy przez długi czas, bo przez ok. 2000 lat, pilnie strzegli tajemnicy pozyskiwania jedwabnych nici i bogacili się na eksporcie tkaniny na zachód, tzw. jedwabnym szlakiem, czyli drogą handlową łączącą Chiny z Bliskim Wschodem i Europą, która swoją nazwę zawdzięcza właśnie jedwabiowi.

Kiedy już tajemnica przestała być tajemnicą, produkcja jedwabiu zaczęła się szerzyć w Azji, a następnie w Europie. W Polsce na dobre zaczęła się rozwijać po odzyskaniu niepodległości w 1918 r.

Historia jedwabiu milanowskiego

Rodzeństwo Witaczków zamiłowanie do jedwabiu miało w genach. Henryk kształcił się z hodowli morwy i jedwabników podczas pobytu w Gruzji. Tam także rozpoczął pracę w fabryce jedwabiu zarządzanej przez swojego ojca, gdzie pracował na każdym etapie produkcji, od rozwijania obrzędów jedwabnych, przez tkanie, po farbowanie tkanin i przędz. Wszystko to po to żeby zgłębić tajniki jedwabnictwa i rozwijać je w Polsce.

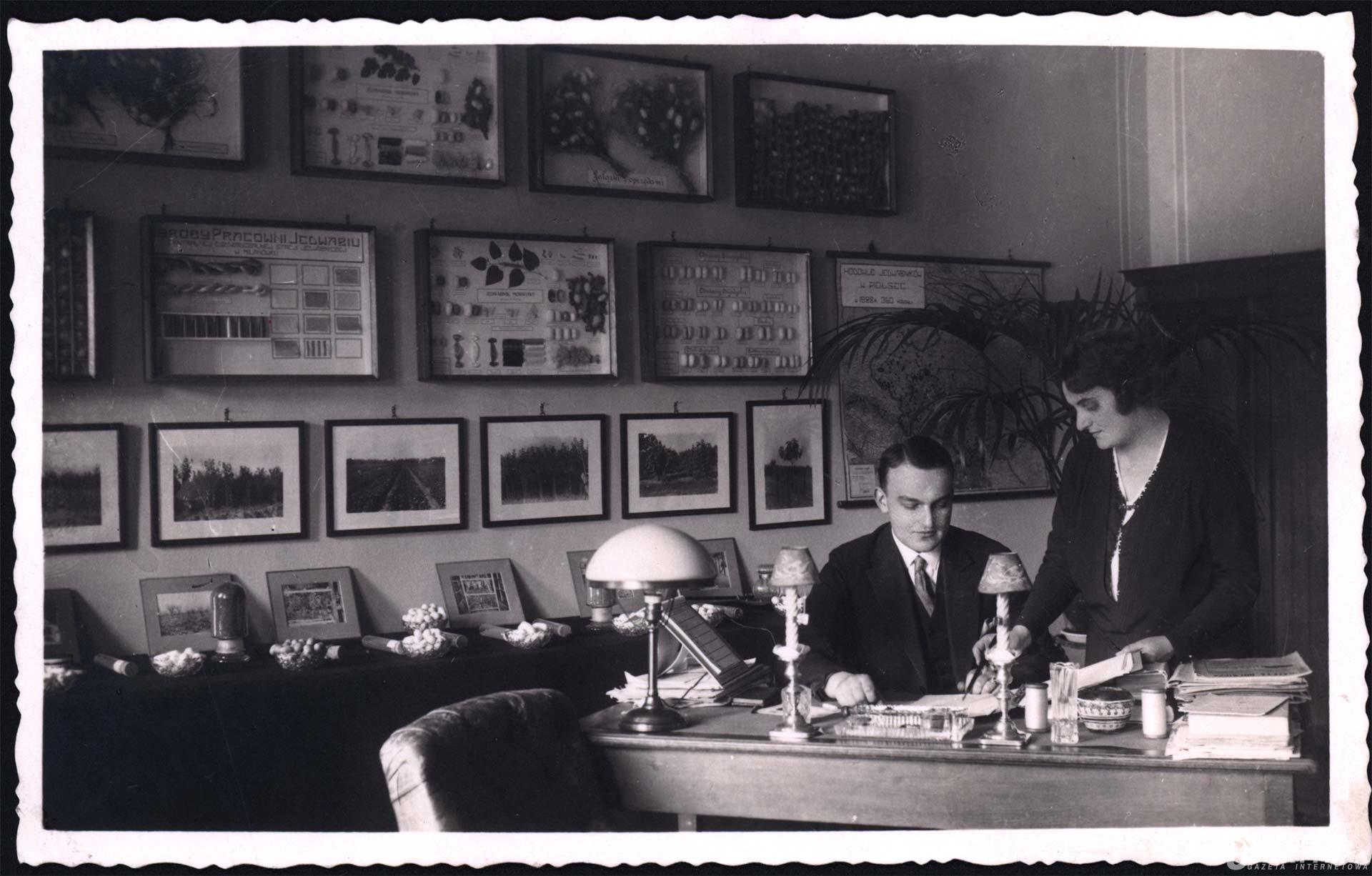

Wmurowanie kamienia węgielnego pod budowę Centralnej Doświadczalnej Stacji Jedwabniczej na zdj. m.in. Henryk Witaczek

W 1924 r. Henryk Witaczek wraz z siostrą Stanisławą, mimo braku poparcia otoczenia, założyli w Milanówku Centralną Doświadczalną Stację Jedwabniczą, przedsiębiorstwo o charakterze badawczym. Na początku zajmowali się nauczaniem i popularyzacją hodowli jedwabników oraz sadzenia i uprawy morwy.

Kiedy w Polsce popularna stała się uprawa morwy okazało się, że ktoś musi zająć się skupem i przerobem kokonów. CDSJ, z założenia instytucja badawcza, rozpoczęła wówczas zajmowanie się kolejnym etapem przetwarzania jedwabiu. Drewniane urządzenia do obróbki włókien zaprojektował Henryk Witaczek.

Budynek Centralnej Doświadczalnej Stacji Jedwabniczej Milanówek zbiory M. Dygas i Cyfrowego Archiwum Tradycji Lokalnej w Milanówku (CATL) M. Koszuta

Z czasem zaczął wzrastać popyt na jedwab na rynku, co sprzyjało uprzemysławianiu się zakładu Witaczków oraz powiększaniu zasobów ludzkich, pracujących nad coraz to szerszym asortymentem oferowanych produktów. Produkowano klasyczne tkaniny z jedwabiu, taftę, płótno z greży, krepę, sprzedawano kupony sukienkowe, apaszki i krawaty, a także fantazyjne tkaniny dekoracyjne, obiciowe i sztandarowe.

Praca przy oprzędach - zbiory M. Dygasi (CATL) M. Koszuta

W latach ‘30 firma posiadała swoją sieć eleganckich sklepów „Milanówek”, a jedwab milanowski cieszył się dużą renomą. Firma współpracowała z Akademią Sztuk Pięknych, która projektowała wzory tkanin.

Prężny rozwój firmy został brutalnie przerwany przez wybuch II Wojny Światowej. W czasie wojny Henryk Witaczek nadal kierował firmą, ale Niemcy przysłali komisarza nadzorującego, a produkcja skupiona była głównie na spadochronach dla wojska.

Witaczkowie bardzo zaangażowali się w działalność społeczną w tym czasie. Dzięki fabryce udało się uratować wiele ludzkich istnień od ulicznych łapanek, oferując prawdziwe lub fikcyjne zatrudnienie. Również właśnie w czasie okupacji zaczęły powstawać pierwsze ręcznie malowane tkaniny - wszystko po to żeby dać zatrudnienie jak największej liczbie osób.

Witaczkowie przyjmowali uchodźców z kresów wschodnich, a także z Warszawy. Zlikwidowany sierociniec ks. Baudouina z Warszawy przeniósł się właśnie do Milanówka, a na terenie fabryki przechowano sprzęt Szpitala Dzieciątka Jezus. Henryk Witaczek wspierał działalność AK, a także tajne Liceum Ogólnokształcące działające w Milanówku.

Niestety po wojnie Witaczkowie zostali pozbawieni dobytku swojego życia - fabryki, którą założyli i pięknie rozwijali przez lata. Warto pamiętać o ich zasługach dla polskiego jedwabnictwa. To oni przyczynili się w dużej mierze do popularyzacji tego rzemiosła - edukowali, zatrudniali, rozwijali technologię produkcji, a także kreowali trendy modowe w latach ’30.

Po wojnie zlikwidowano wszystkie sklepy firmowe, a samą firmę przemianowano na państwowe Zakłady Jedwabiu Naturalnego „Milanówek”. Zakłady kontynuowały tradycję ręcznie malowanych oraz drukowanych jedwabnych tkanin, zdobywając uznanie w Polsce i na świecie. Produkowane tu tafty, atłasy, apaszki, krawaty i szaliki stały się synonimem luksusu w szarej rzeczywistości PRL.

Tradycja hodowli jedwabników, stanowiąca o wyjątkowości Milanówka w skali kraju, zaczęła podupadać w latach ‘80, a przemiany gospodarcze lat ‘90 doprowadziły do całkowitego wstrzymania jego produkcji.

Na szczęście w Milanówku wciąż kultywowana jest tradycja malowania na jedwabiu.

Rodzeństwo - Henryk i Stanisława Witaczek fot.: https://www.obiektywna.pl/Milanowek/rodzina-witaczkow3

Wyjątkowość jedwabiu

Naturalny jedwab to jedyne włókno, z którego można wytworzyć różne materiały - i zwiewny habotai, i gruby żakard, a także wiele innych.

Co sprawia, że jedwabna tkanina jest delikatna i lśniąca, ale jednocześnie mocna i elastyczna? Jedwab jest jednym z najcieńszych włókien naturalnych, a jego budowa jest bardzo specyficzna. Fibroina, stanowiąca podstawę włókna jedwabnego, to substancja białkowa wykazująca niezwykłą wytrzymałość, a jednocześnie elastyczność. Trójkątny przekrój włókien sprawia, że światło załamywane jest jak w pryzmacie.

Dzięki temu, że jedwabna tkanina jest higroskopijna (wchłania wilgoć), chłodzi podczas upału i grzeje w czasie chłodu. Ponadto jedwab nie wywołuje alergii, a nawet odstrasza wszy, pchły i inne pasożyty.

Ta niezwykła tkanina ma zastosowanie nie tylko w modzie, ale także m.in. w chirurgii czy w instrumentach muzycznych. Kiedyś była używana w spadochronach, a także zdobiła ściany królewskich pałaców.